สวัสดีทุกคน! วันนี้เราจะมาเรียนรู้เกี่ยวกับสิ่งที่ยอดเยี่ยมมากอย่างหนึ่ง: การพิมพ์ 3D คุณอาจจะยังไม่เคยได้ยินเกี่ยวกับการพิมพ์ 3D แบบ SLA และ DLP เหล่านี้เป็นสองรูปแบบที่แตกต่างกันของการสร้างสามมิติซึ่งหมายถึงการทำวัตถุที่คุณสามารถจับได้และมองจากทุกด้านจริง ๆ เพื่อเข้าใจวิธีเหล่านี้ได้ดีขึ้น เราจะมาดูกันว่าพวกมันแตกต่างกันอย่างไร!

คำศัพท์เหล่านี้หมายความว่าอย่างไร ก่อนอื่นเรามาดูสรุปสั้น ๆ เกี่ยวกับคำศัพท์เหล่านี้กันก่อนแล้วค่อยไปต่อ SLA เป็นคำย่อของ Stereolithography ซึ่งเป็นกระบวนการที่สร้างวัตถุด้วยการใช้เลเซอร์ โดยการทำให้เลเซอร์ชี้ไปที่ของเหลวชนิดหนึ่งที่เรียกว่าเรซิน ซึ่งจะเปลี่ยนรูปแบบเมื่อโดนลำแสงเลเซอร์ (มันจะแข็งตัว) เลเซอร์จะสร้างวัตถุขึ้นมาทีละชั้นจนเสร็จสมบูรณ์ ส่วน DLP หมายถึง Digital Light Processing ในทางกลับกัน วิธีนี้ก็ใช้เรซินของเหลวเช่นกัน แต่แทนที่จะใช้เลเซอร์ จะใช้โปรเจ็กเตอร์แสงในการทำให้เรซินแข็งตัว แสงจะถูกใช้เพื่อฉายภาพของวัตถุลงบนชั้นเรซินพร้อมกันทั้งหมด ซึ่งช่วยให้การพิมพ์เร็วขึ้น

ดังนั้น คุณอาจถามว่าความแตกต่างที่สำคัญที่สุดระหว่างสองวิธีนี้คืออะไร วิธีการทำให้เรซินแข็งตัวเพื่อสร้างวัตถุทางกายภาพเป็นจุดเด่นที่แตกต่างกันหนึ่งประการ SLA จะใช้เลเซอร์กำหนดเป้าหมายทีละจุด ดังนั้นการออกแบบขนาดจุลทรรศน์จึงเป็นไปได้ ในขณะที่ DLP จะฉายแสงลงบนชั้นทั้งหมดพร้อมกัน ซึ่งอาจเร็วกว่า SLA แต่อาจไม่สามารถจับรายละเอียดเล็กๆ ได้ดีเท่า SLA ตอนนี้ SLA มีชื่อเสียงในเรื่องของความแม่นยำและความถูกต้อง ในขณะที่ DLP มีข้อดีในเรื่องความเร็วสูง

การพิมพ์แบบ SLA และ DLP ต่างก็มีข้อดีที่ยอดเยี่ยมมากมาย เหมาะอย่างยิ่งสำหรับงานที่ต้องการความละเอียดสูงเนื่องจากคุณมักจะต้องการให้งานที่ออกมาดูสมบูรณ์แบบ นอกจากนี้ยังเหมาะมากหากคุณต้องการผลิตภัณฑ์เพียงไม่กี่ชิ้นก่อนที่จะทำการผลิตจำนวนมาก ซึ่งเป็นประโยชน์ในอุตสาหกรรมที่ต้องการทดสอบการออกแบบก่อนที่จะขยายขนาดลง

อย่างไรก็ตาม เทคโนโลยีเหล่านี้ยังมีข้อเสียหรือข้อจำกัดบางประการ การพิมพ์แบบ SLA มักจะมีราคาสูงกว่าเพราะใช้เลเซอร์เทคโนโลยีสูงและวัสดุที่อาจมีราคาแพงมาก แต่การพิมพ์แบบ DLP อาจให้ผลลัพธ์ที่มีคุณภาพแย่กว่าในบางกรณี เพราะโปรเจ็กเตอร์มีตารางพิกเซล ดังนั้นมันจึงไม่สามารถจับรายละเอียดทั้งหมดของการออกแบบของเราได้

ความแม่นยำ / การพิมพ์แบบ SLA: โดยทั่วไป เมื่อพูดถึงความแม่นยำในการพิมพ์ 3D การสนทนาจะมุ่งเน้นไปที่ SLA การใช้เลเซอร์ที่กำหนดเป้าหมายแต่ละชั้นแยกกัน ทำให้เครื่องพิมพ์ 3D นี้สามารถสร้างงานพิมพ์ < ที่แม่นยำกว่าเครื่องอื่นๆ ซึ่งเป็นเหตุผลว่าทำไมงานพิมพ์ถึงมีรายละเอียดคมชัดมากมาย ในทางกลับกัน แต่ละชั้นจะได้รับแสงที่ไม่ชัดเจนทั้งหมดพร้อมกันผ่านการพิมพ์แบบ DLP ส่งผลให้เกิดการสูญเสียรายละเอียดในงานพิมพ์สุดท้าย แม้ว่าจะเป็นเช่นนั้น การพิมพ์แบบ DLP มักจะเร็วกว่า SLA เพราะสามารถทำให้ชั้นทั้งหมดแข็งตัวได้ในครั้งเดียวแทนที่จะทำจุดเดียวทีละจุด

ดังนั้นเราได้เรียนรู้ว่าทั้ง SLA และ DLP เป็นกระบวนการสองแบบที่แตกต่างกันสำหรับการพิมพ์ 3D แต่ละวิธีเหมาะสมสำหรับการผลิตในปริมาณที่น้อยซึ่งอาจใช้ในการทดสอบสินค้าหรือขนาดของตัวอย่างจำลอง (prototype) SLA จะช้ากว่าแต่ละเอียดกว่า ในขณะที่ DLP จะเร็วกว่าและมีประสิทธิภาพมากขึ้น อย่างไรก็ตาม สุดท้ายแล้วมันขึ้นอยู่กับว่าอะไรเหมาะสมที่สุดสำหรับความต้องการเฉพาะของโครงการของคุณ

ตั้งแต่ SLA และ DLP ผู้ก่อตั้งของเราได้ทำงานกับเครื่องพิมพ์ 3D มาโดยตลอดตั้งแต่ FDM ไปจนถึง DLP, SLA เขาเชื่อว่า "เทคโนโลยี 3D จะสร้างการปฏิวัติครั้งใหม่ในภาคอุตสาหกรรม" เราทำอย่างเต็มที่เพื่อให้การสนับสนุนทางเทคนิคและการบริการแก่ผู้ที่ชื่นชอบเครื่องพิมพ์ 3D และสนับสนุนเราอย่างแข็งขัน! เราให้บริการอย่างสุภาพและตอบสนองความต้องการของตลาดอย่างรวดเร็ว

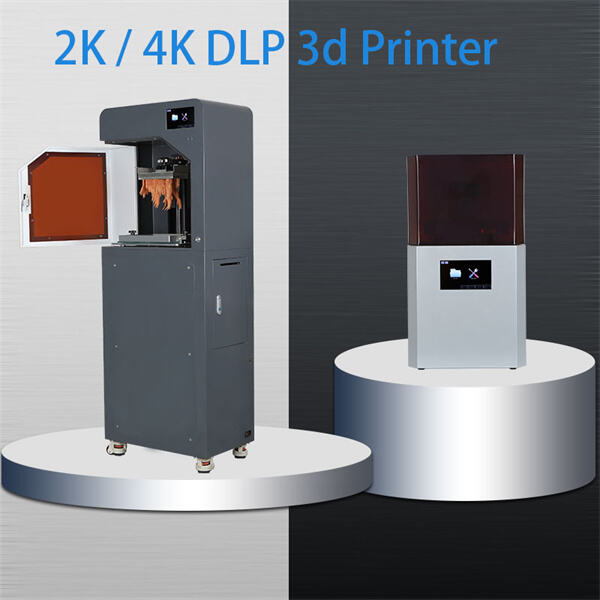

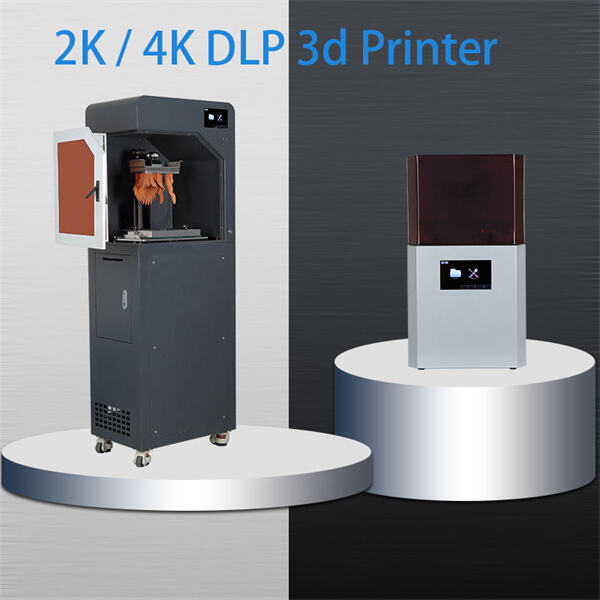

เทคโนโลยี sla และ dlp ของเราได้ถูกใช้งานในหลากหลายอุตสาหกรรม เช่น เครื่องประดับ ทันตกรรม เซรามิกส์ และอื่น ๆ อีกมากมาย บริการแบบกำหนดเองของเรานั้นเหมาะอย่างยิ่ง บริการเหล่านี้รวมถึงการออกแบบลักษณะpearance การออกแบบโลโก้เฉพาะ การออกแบบซอฟต์แวร์ เพิ่มฟังก์ชันการทำงาน และแพคเกจจิ้งส่วนตัว เราให้ลูกค้าของเราด้วยเครื่องพิมพ์ 3D ในราคาที่เป็นมิตรที่สุด พร้อมคุณภาพ ประโยชน์ใช้สอย และประสิทธิภาพสูงสุด

บริษัท Shenzhen 3KU Technology and Science Co. LTD ก่อตั้งขึ้นในปี 2014 ภายในระยะเวลาไม่กี่ปีของการตลาดและการพัฒนา แบรนด์ 3KU ของเราเป็นที่รู้จักอย่างดีในกลุ่มผู้ใช้งานเครื่องพิมพ์ 3D ประเภท sla และ dlp เราให้การสนับสนุนทางเทคนิคครบวงจร เทคโนโลยีการพิมพ์ กระบวนการหลังการหล่อ และการรับประกันตลอดชีพ นอกจากนี้เรายังมอบเทคโนโลยีระดับมืออาชีพและบริการแบบกำหนดเองเพื่อช่วยแก้ปัญหาการหล่อและการพิมพ์ในหลากหลายสาขา

ด้วยการออกแบบและก่อสร้างที่โดดเด่น โดยเฉพาะอย่างยิ่งทีมวิจัยชั้นนำของเรา ทำให้เครื่อง sla และ dlp ของเราถูกใช้งานในหลากหลายอุตสาหกรรม เช่น การหล่อฟันและการทำมงกุฎฟัน การหล่อเครื่องประดับ การทำชุดอุปกรณ์สำหรับโรงรถ การหล่อแบบแม่นยำ เป็นต้น เราให้บริการตัวอย่างฟรี คุณสามารถส่งไฟล์ STL มาให้เรา และเราจะพิมพ์ออกมาด้วยเครื่องพิมพ์ของเราเพื่อแสดงว่ามันทำงานอย่างไรและผลลัพธ์เป็นอย่างไรก่อนที่คุณจะซื้อ

ลิขสิทธิ์ © Shenzhen 3KU Technology and Science Co., LTD. สงวนสิทธิ์ทั้งหมด นโยบายความเป็นส่วนตัว บล็อก